Features

Our high speed side automatic sealing and cutting machine is suitable for a range of shapes folds and pockets, interlinking with other equipment to be able to make even more types of bags for easy exchange. Some examples of pattern types include: punching equipment for round holes, butterfly holes, utilizes handheld punching equipment for accuracy and can produce perforations for letter and packaging tear off strips.

Using a vertical up and down heat sealing system and supersonic sealing line device means improved sealing quality and can also produce anything from 'V' type standing pouches to handbags.

If this isn't enough, we also can provide extra parts for improved production accuracy and quality, this includes EPC edge sensor, servo motor to drive the machinery and an automatic conveyer to get your finished products to the packing section as soon as possible. This machine is also suitable for already perforated and/or folded films.

Read also : QUICK GUIDE TO SIDE SEAL BAG MAKING MACHINE

Advantages

World Steel's side sealing and cutting machines are produced to cut down on manpower, able to provide up to 220PCS/min (depending on the bag size and material). Compared to other bag making machines in the same class the system provides easy and high quality sealing. With the advent of industry 4.0 our machinery has also fully embraced automation. With an electric automatic control system, automatic positioning when stopping, a high precision electric eye device to place accurate printing marks and a device that automatically stops the machine when encountering anomalies in the production process. This plus an imported long life conveyor belt and the option to produce a variety of plastic bags, packaging bags, stand up bags and more makes this the perfect choice for your factory.

Specification

-

- MODEL

- Width of Bag

- Length of Bag

- Production Capacity

- Heater

- Motor

- Power Required

-

Packing Dimensions

(L X W X H M)

-

- WS-220S

- 2-20 cm

- Max.45 cm

- Max.220 Pcs/Min

- 2.2 KW

- 2HP

- 6KW

- 4 X 1.5 X 2.1

-

- WS-260S

- 5-60 cm

- Max. 60 cm

- Max.220 Pcs/Min

- 2.2 KW

- 2HP

- 6KW

- 4.2X 1.5 X 2.1

-

- WS-320S

- 5-60 cm

- Max. 76 cm

- Max.200 Pcs/Min

- 2.5 KW

- 2HP

- 6.5KW

- 4.2 X 1.65 X 2.1

-

- WS-430S

- 5-60 cm

- Max. 96 cm

- Max.150 Pcs/Min

- 2.7 KW

- 2HP

- 7KW

- 4.2 X 1.85 X 2.1

Applications

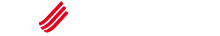

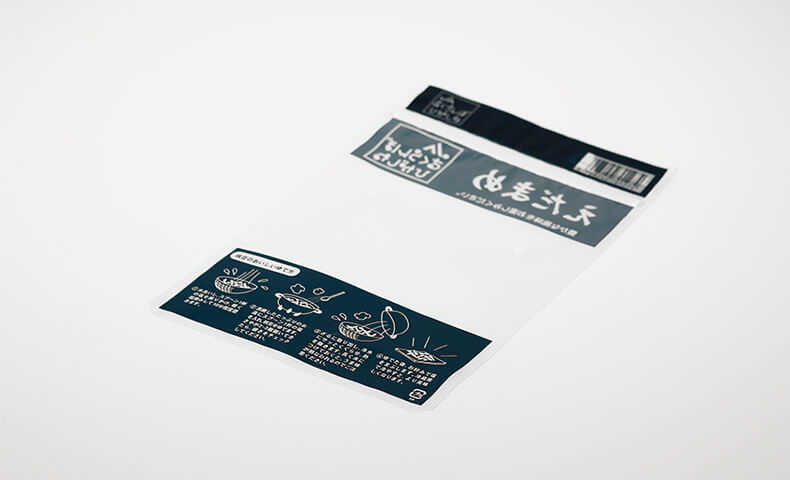

- - Book Sleeves

- - Self Adhesive Bags

- - Hang bags

- - Sanitary bags

- - Chicken bags

- - Shopping bags

- - Vegetable and fruit breathable bags

- - Courier bags

- - Toilet paper bags

- - Diaper Bags

- - Zipper bag

- - PP information book page

Suitable Raw Materials

- - Suitable for single layer roll films such as PP, OPP, BOPP, CPP, LDPE and HDPE.